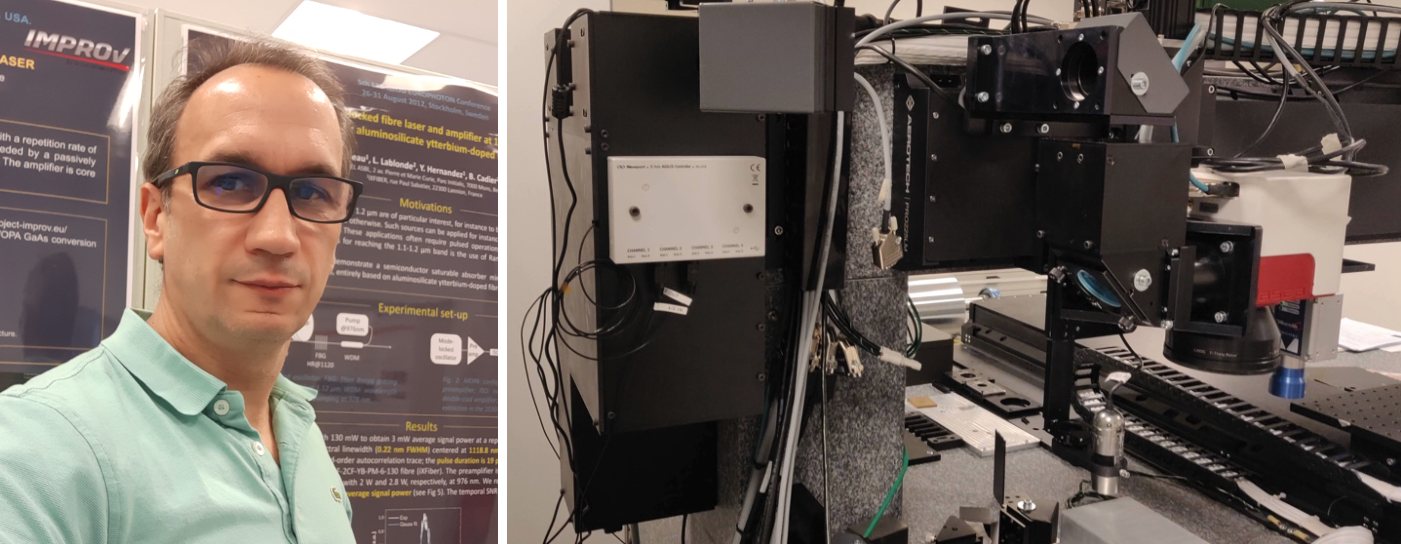

From learning about LIPSS to coping with coronavirus, Dr Yves Hernandez, Head of Applied Photonics at Multitel, explains how he and colleagues made the modules that bend and shape the Laser4Surf laser.

You have been working in Applied Photonics at Multitel for 17 years – how has the department evolved over this time?

Hernandez: The Multitel research centre was created in 1995, and the photonics department historically developed fibre lasers for a range of applications. We still work with these lasers now, but about ten years ago we also started to get more involved with micromachining. We were developing high energy, short pulse lasers that were designed for micromachining but always had to rely on a partner, such as LASEA, to evaluate these for us. So at some point we thought, why not make a small lab at Multitel to evaluate the performance of our own lasers? We also received a lot of interest from different partners and after a short while, this lab really started to grow. This wasn’t something that we had really planned from the beginning, but it naturally developed.

During this time you developed a unique laser micromachining system – tell us more.

Hernandez: Our laboratory system, designed for development, is very different to other instruments in that it’s flexible, and like an open machine. We can change anything in it: the laser itself, its wavelength and polarization orientation – even the pulse duration. We can also alter the laser beam-shaping and beam-scanning, which is really useful when you are working on process development. When you start a project you might not have a clue as to whether you need a femtosecond, picosecond, nanosecond or a continuous-wave laser. But with our system you can change the set-up and then study all potential parameters, such as laser scan speed and repetition rate, to see what does the job better. This very flexible micromachining system has brought us many collaborations and has become a real activity in the lab.

Why join Laser4Surf?

Hernandez: We’ve been involved with many European projects, interacting with many partners and gaining a lot of expertise on how to handle lasers for many different materials and processes. However, Laser4Surf gave us the opportunity to learn more about Laser-Induced Periodic Surface Structures (LIPSS). In the past, we’d carried out a few LIPSS trials but with Laser4Surf we realised we could learn a lot more about these processes and the different ways to control the operation of a LIPSS system and create regular patterns on different materials. Importantly, the project also gave us an opportunity to collaborate with new partners, such as CEIT, Rescoll and Fagor Automation. And as a research centre, Multitel likes to support companies from its region – with Laser4Surf we’ve been able to reinforce our collaboration with LASEA, another Belgian company that we have been working with for years.

What has been your key contribution to Laser4Surf?

Hernandez: We have focused on the LIPSS system’s laser beam handling and polarization control. Here we make sure the laser has a uniform beam shape to optimise the energy transferred from the laser light to the material so we can generate regular patterns on the surface of a material. The orientation of LIPSS patterns also depends on the laser’s polarization, so we control this parameter as well. To achieve all of this we use mirrors and diffractive optics to guide the laser beam, and alter its shape and polarisation for creating the necessary pattern. As part of our set-up we have also included a spatial light modulator that uses a matrix of liquid crystals to modify the laser beam. Critically, each liquid crystal is driven independently so you can alter the beam to precisely create the pattern that you want. You can even use the spatial light modulator to correct deviations in real-time. All of these components have been designed into two ‘beam shaping’ modules that we have integrated into the Laser4Surf LIPSS machine.

What were the key challenges when developing these beam shaping modules?

Hernandez: The process of designing the modules, building the prototypes and integrating them into the Laser4Surf machine that has been built by our partner LASEA, was very important. We bought a lot of the components, such as the spatial light modulator, but a critical part was designing all of these components into the modules that would then fit perfectly into the machine and also match its laser power, optics and software. Given this, one of the first things that we did at the beginning of the project was to get a detailed description of how the interfaces between our modules and the Laser4Surf machine were to operate together, and based on that, we developed these to match the requirements.

How have you kept the costs of your modules to a minimum?

Hernandez: At the beginning of the project we were concerned as we knew we would be working with different materials – copper, aluminium and titanium alloys – for the different applications. We thought we would need to develop different modules to be compatible with different lasers as some materials can be more effectively patterned with, say, an infrared laser than a green laser. But as our work progressed, we realised that the LIPSS system could use infrared light for all of its applications, which helped us to simplify and make the entire process more cost-effective. Also, assembling the modules with the components that we bought has been cheaper than simply buying a complete commercial solution, and this has also allowed us to build an overall set-up that can be more easily integrated to the final machine.

Where do you think the Laser4Surf machine will be used?

Hernandez: The machine has been developed to be flexible enough to cope with the three key applications – batteries, optical encoders and medical implants – and can be used in different ways. For example, with the encoders, we need to carefully control the beam-shape during the LIPSS process to induce the regular sub-micron relief structures needed for accurate position feedback. However, if we look at batteries, we don’t require so much beam-shaping here but instead need to alter the polarization of the laser light. This is to enhance the roughness of the surface of the battery’s current collector, which improves the battery’s electrochemical properties and extends its life. Before the COVID-19 crisis, we were also evaluating the system for biosensor applications – this has stopped for the time being but is one example of the many other applications where we expect the Laser4Surf machine to be used.

The coronavirus pandemic is delaying many projects right now – when will we see the beam shaping modules and micromachining system in action?

Hernandez: We installed our modules to LASEA’s micromachining system before the COVID-19 crisis, but since shutdown we have not been able to get back to the company to run tests and continue system implementation, which is a real pity. Towards the end of any project it is natural to ‘run out of time’ as you tend to accumulate different delays along the way but the crisis has only added to this. However, we believe that if the system is tested from July to the end of this year, and if no problems appear, then the system will be ready to use quickly afterwards. This isn’t a lab experiment – it’s been designed to be a system that other companies will find easy to use, and I don’t expect any issues here.