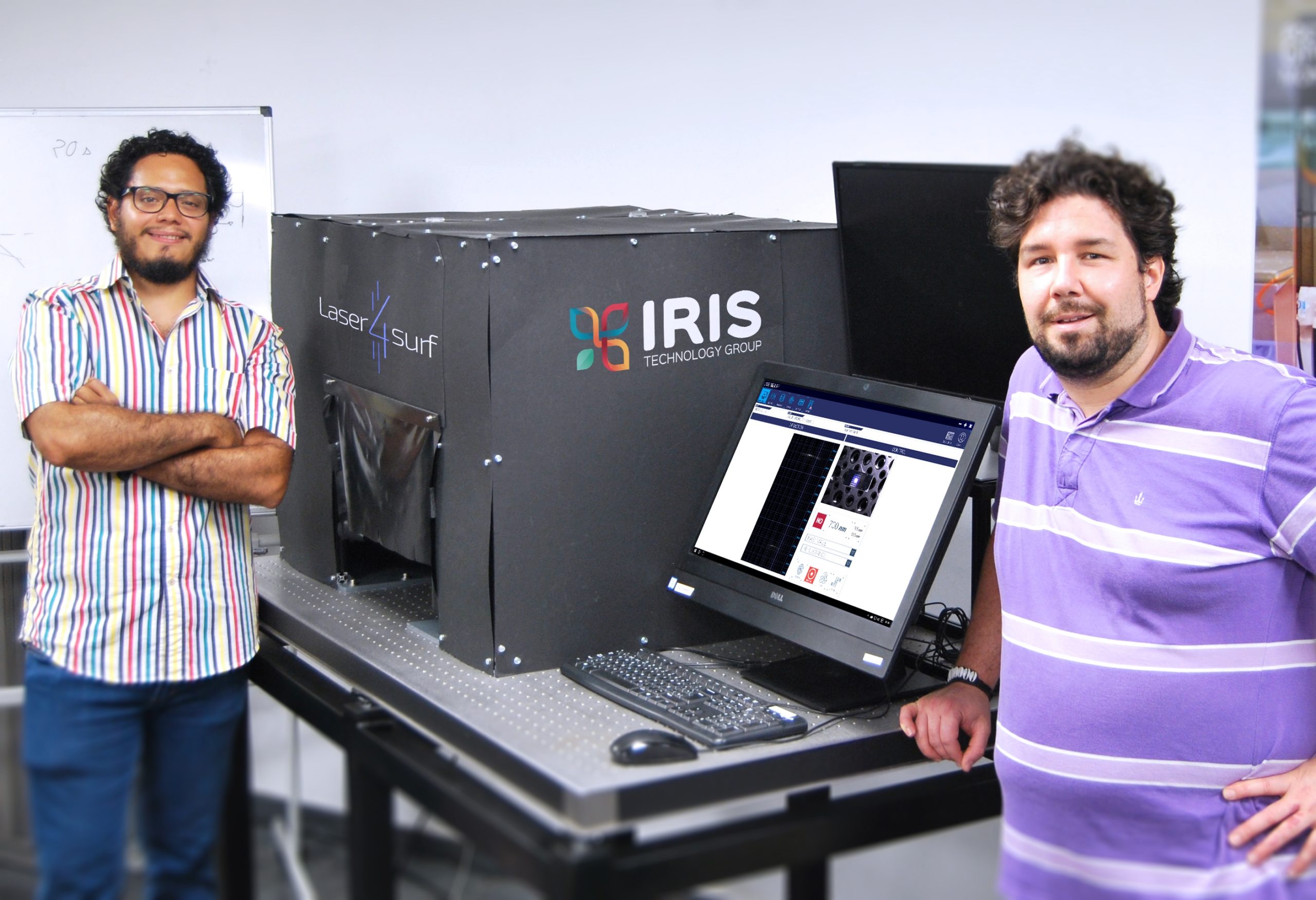

Be it surface ablation on a medical implant or nanobubble formation in an encoder – Spain-based engineers have built an in-line monitoring unit to detect defects during laser structuring of material surfaces. Dr Aldo Ramirez Reyes and Dr Laurent Philippet from IRIS Technology Group talked to ESCI about the challenges of setting up the system, the importance it has to Industry 4.0 and how coronavirus pushes the need for automated systems.

Dr Aldo R. Reyes, you are Project and Innovation Manager, could you tell us a little about what your company specialises in?

Reyes: Based in Barcelona, the IRIS Technology Group is an advanced engineering company that aims to make industry smarter, more sustainable and efficient. In general, we develop process monitoring, control and optimisation solutions based on near-infrared and hyperspectral spectroscopies, and other optical technologies, and we often link these to data management or artificial intelligence to optimize processes. We have a wide expertise in digital transformation, and develop so-called SMAC – social, mobile, analytics and cloud – platforms for industrial applications.

We also develop analytical models for a range of applications, to help customers with process development.

Dr Laurent Philippet, as Senior Optical Engineer, could you tell us more about your company’s role in the Laser4Surf project?

Philippet: Laser4Surf has been developing an integrated laser texturing prototype that includes an optical module to texturize the surface of different materials. At the end of the texturizing process, we want to check that texturization took place according to the parameters set initially by the customer. This quality control step is important as it will define the physical and/or chemical functions given to the sample – for example osteo-compatibility in the case of medical implants provided by partner RESCOLL.

Reyes: To achieve this, we have been developing an in-line monitoring unit that will be used as part of the quality control system of the prototype. In-house, we have developed software based on predictive models that assess the quality of the sample’s surface. To accompany this, we have developed a user-friendly guide that also includes training for the new technology. Importantly, the unit monitors the texturized surfaces at the micro- and nano-scale in real-time, using optical diffraction, providing a quick in-situ response, as required by industry.

In-line monitoring systems are widely used to monitor the quality of many processes during production – could you tell us how your in-line monitoring unit works and why you have developed a system based on diffraction?

Philippet: The Laser4Surf laser texturizes the surface of a material, producing a pattern of periodic micrometre or nanometre-scale, almost parallel grooves that we call laser-induced periodic surface structures (LIPSS). When you direct light at these LIPSS, the rays are diffracted depending on the properties of the light and surface structures. By analysing the complex diffracted pattern produced when we shine the light at these LIPSS, we can then work out the precise parameters of these structures. Importantly, we also use this diffraction technique to monitor the quality of the LIPSS during texturizing, which isn’t trivial. As part of this we’ve built predictive models that compare diffraction data from past calibrated texturized samples with data from the current surface, to calculate the probability of a defect forming. Each different material requires a different predictive model to be built. We can use the in-line system to detect surface ablation, which takes place when the texturing laser power is too high and the scanning speed too slow as well as nanobubble formation, which also affects the quality of a texturized surface, and final functionality for the customer.

During development, what have been the key challenges of setting up a system to monitor these defects and variations in quality?

Reyes: To my mind, there have been two big challenges. First, the actual in-line monitoring system has to be able to adapt to, and operate with many different types of materials, applications and processes. This is a big technical challenge and we are still working on some small details here. Also, when you are building your predictive model, you base it on a digital library that, in effect, has all the answers to all of your possible questions. However, if your model can’t be applied to a particular sample, then you have to adapt that model as well as also your monitoring system.

Philippet: That’s absolutely right. For the engineer, the real challenge is always to integrate all of your modules so they work in a full, smooth and continuous process. Sometimes the fundamental physics of what you are doing is not that complex, but developing an industrial system that can be applied to a variety of different shapes and types of material, and then integrate this into a customer factory with other modules – well, that is not straightforward. For example, communication between different software packages can be an issue, and sometimes when you put everything together in a factory, mechanical vibration or electric noise can emerge and interfere. It’s not like in a laboratory where you can control your conditions – making a full product and integrating it with other systems that will work end-to-end is challenging.

What is the current state-of-play with the in-line monitoring unit and what are your next steps?

Philippet: We have validated the unit with an encoder end-user test case from FAGOR Automation. We are now finalising how the system will monitor the quality of surface texturizing in titanium implants from RESCOLL and advanced battery collectors, as developed by CIC energiGUNE.

Reyes: Also, what we really need to appreciate with this unique project is that an implant is very different to, say, a battery collector, so we have to be very careful about how we validate the in-line monitoring unit in these different applications. We hope that the final experimental and validation steps will be back on track during the next weeks and would expect the entire project to finish by the end of the year, give or take a couple of months.

Could you tell us a little about the Fourth Industrial Revolution, or Industry 4.0, and explain why systems such as the Laser4Surf in-line monitoring unit are so important here?

Reyes: Industry 4.0 is the name given to the growing combination of traditional manufacturing and industrial platforms with the latest smart technology. It includes increased automation as well as improved communication and monitoring, so issues can be analyzed with minimum human intervention. From a technical point of view, in-line monitoring is really advantageous as it gives you a fully controlled process with fewer human mistakes, leading to better quality products.

Some people worry that Industry 4.0 will bring job losses – do you believe that this topic of ‘robots replacing people’ is an issue?

Reyes: Sometimes this is a tricky field to have an opinion in, as you can struggle with the ethics of saying, yes, it’s okay to automate everything instead of employing people. However, in my opinion, we should see this as transforming jobs, rather than destroying jobs. Workers should be given the tools to tackle this new technological revolution, which means providing the necessary courses and capabilities, and also investing more money into their employment.

Philippet: Yes, of course, Industry 4.0 is creating new kinds of jobs. You will still need people to develop and run the new systems – this isn’t science fiction where machines build machines.

Given the current coronavirus pandemic, is IRIS finding that its automation tools and systems are being requested more?

Reyes: This is a very interesting question. I think this global situation could demonstrate, not only for IRIS but also for any other tool and systems developer, that Industry 4.0 is needed more than ever. It isn’t the future, it’s the present, and companies need to keep on track to stay in the game.

What have been the high-points of Laser4Surf for you?

Philippet: The in-line monitoring system has been a new implementation for us. Monitoring samples using diffraction technique isn’t common in IRIS, in fact this is possibly our first project working with this technology. The novelty had been very interesting and also motivating as we want to show our company that such a system has a future and will make a good investment. Also, we tend to work a lot in the food industry, and while we have pharmaceutical contracts, developing a system for the medical field, as we have in the implant use-case, is new for us, and very cool. We hope it will open new business opportunities for IRIS.

Reyes: Also, the Laser4Surf consortium has been very pleasant to work in – our partners have been great and communications with them have been very good. Let’s hope the final result and full integration is similarly good if not even better.