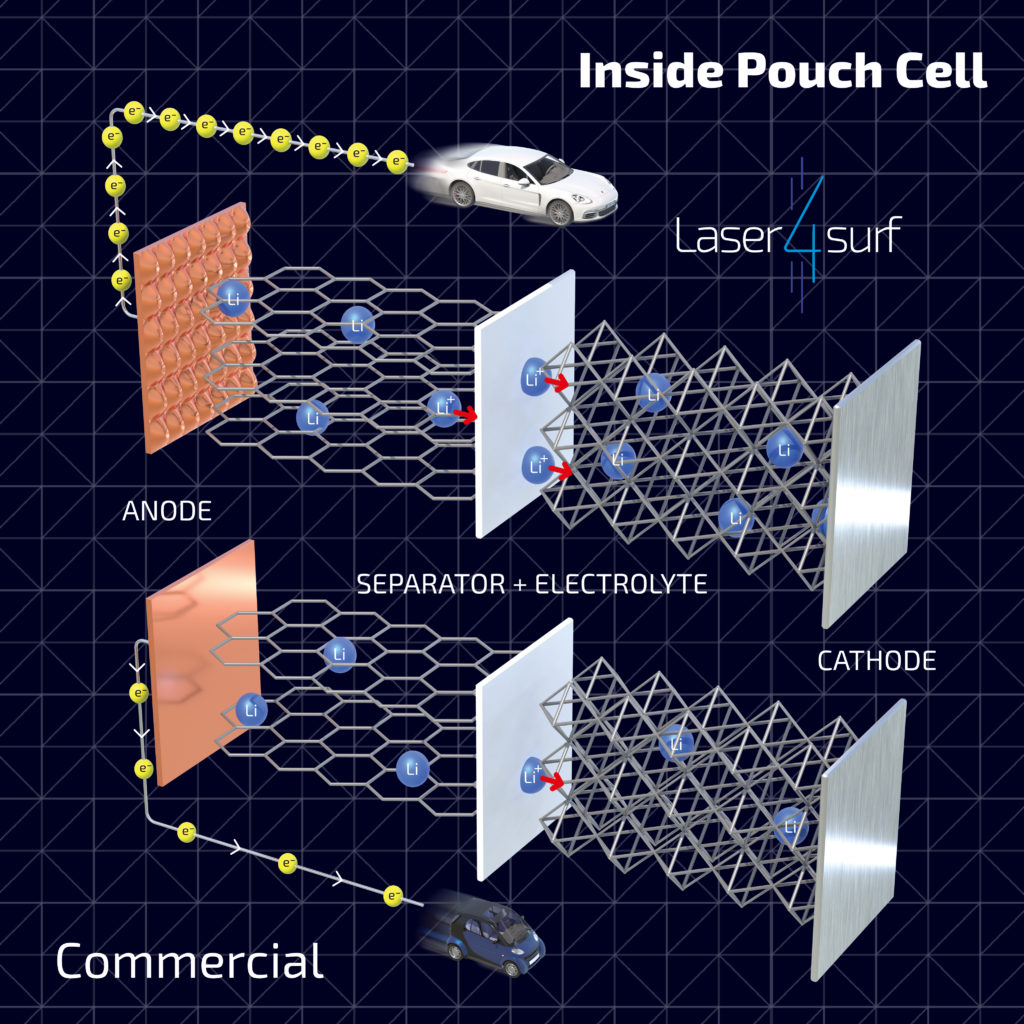

Li-ion batteries are dominant in consumer electronics and power tools. Up to now, the cycle life and safety of Li-ion batteries have been mainly correlated with the electrode material. LASER4SURF will unveil the influence of the current collector surface on preventing overheating and improving cycle life by up to 30%.

Enhanced adhesion and roughening of the current collector with the help of laser-induced periodic surface structuring (LIPSS) will allow controlled changes in the current collector surface very cost-effective and fast way (0.1 min/cm2). It will also improve the electrochemical properties of battery current collectors without using expensive carbon coating methods, harmful etching processes and complex three-dimensional processing methods that have to be used nowadays.

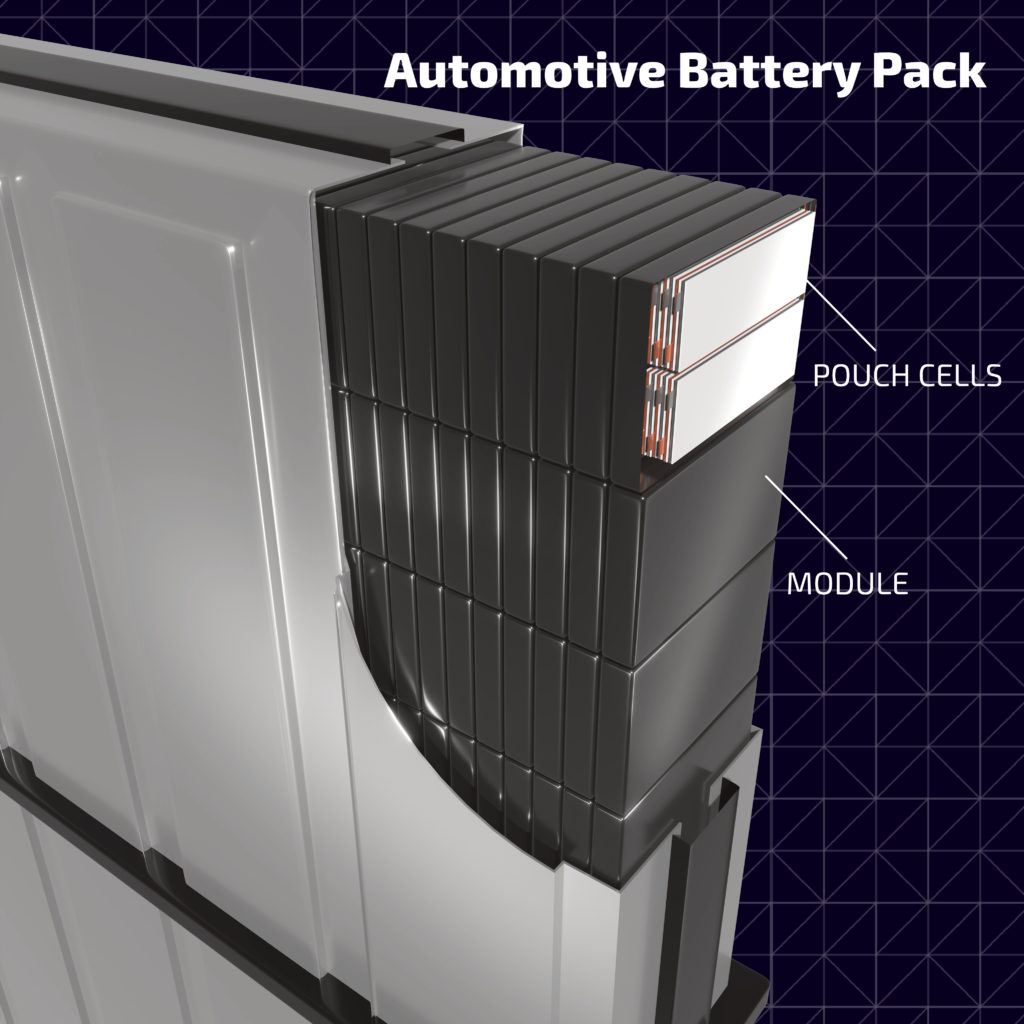

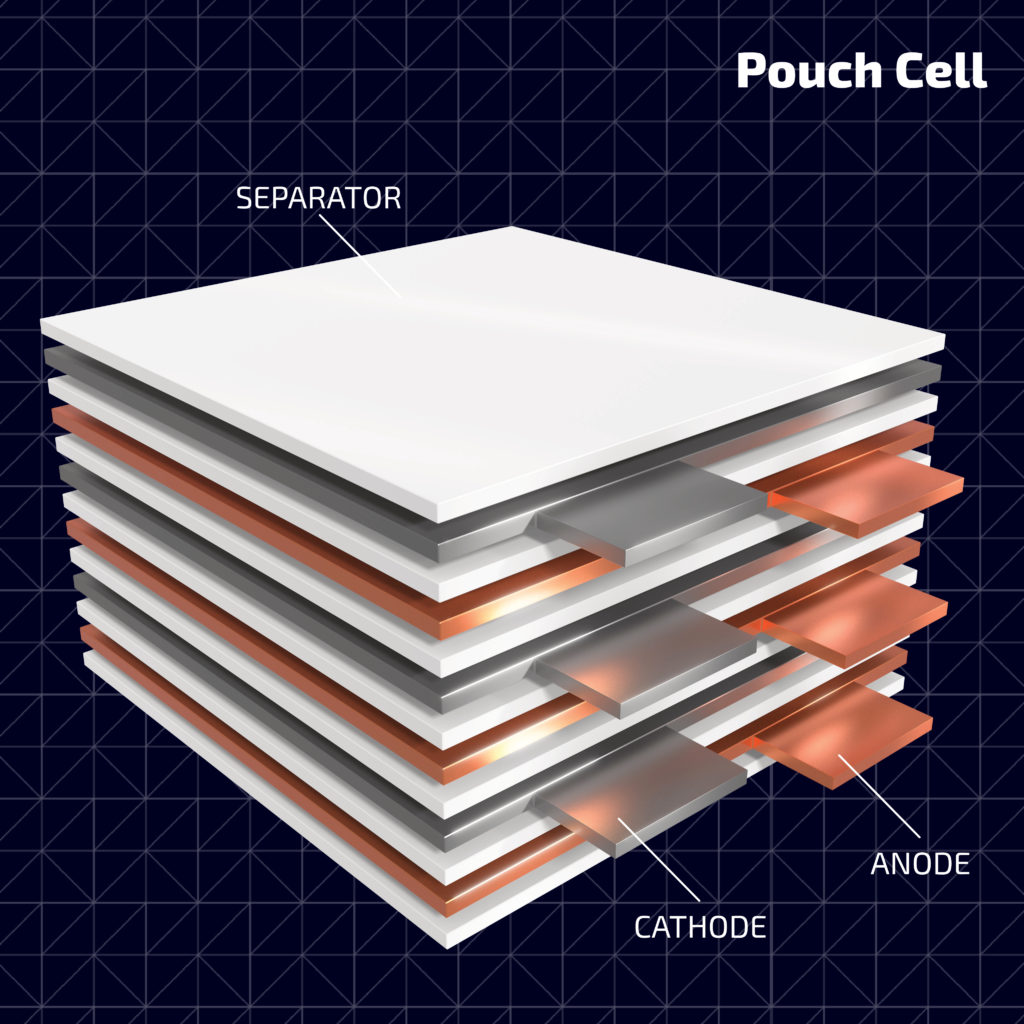

The improvement of the current collector performances (increase mass loading and improving current density) will be validated under industrial requirements of coin cells. Furthermore, the project will study the implementation of the process for larger batteries as used in e-vehicles – a growing market where the current production could be increased 20-fold by 2040 (reaching 48000 km2/year of a collector’s surface!).